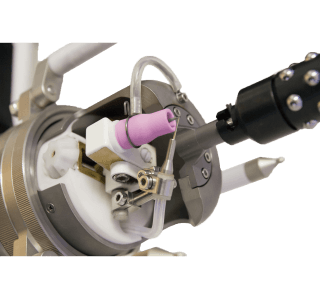

The Model 120 head can weld tubes from only 3 mm diameter up to 40 mm, and with a wall thickness of up to. This is because of its small torch, a lightweight head with high centering efficiency for positioning. There is also a version with pneumatic centering.

Technical Features

Welding process: TIG without wire feed

Welding position: Flat / Vertical

Head positioning: Supported by counterbalance

Torch centering: Self-centering mandrel, or optionally pneumatic centering

Torch refrigeration: water

Diameter of tungsten electrode: 1,0 ÷ 2,4 mm

Electrode positioning: 21 ± 5 mm

Welding current: 100 A DC max Pulsed / 80 A Continuous

Rotation speed: 0,10 ÷ 8,25 rpm

Connection cable: L = 8 m (5,500 Kg)

Power supply voltage: 24 Vdc

Measurements: H= 200 mm ; L=280 mm ; W=90 mm