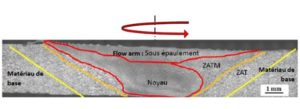

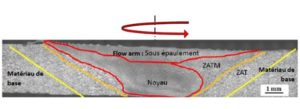

5 zones differentiated in the weld

– Base metal: neither deformations nor heat modify its crystalline structure

– Heat Affected Zone (HAZ): no deformation due to the tool

– Thermo-Mechanical Affected Zone (TMAZ): is affected by heat and major plastic deformations. We see a rotation of the grains and the appearance of restoration and recrystallization phenomena

–Core: dissolution of precipitates, important deformations through which recrystallization occurs and new crystalline structures (small equiaxial grains)

Arm of Flow (Flow-arm): Recrystallized area, forged by the shoulder of the tool

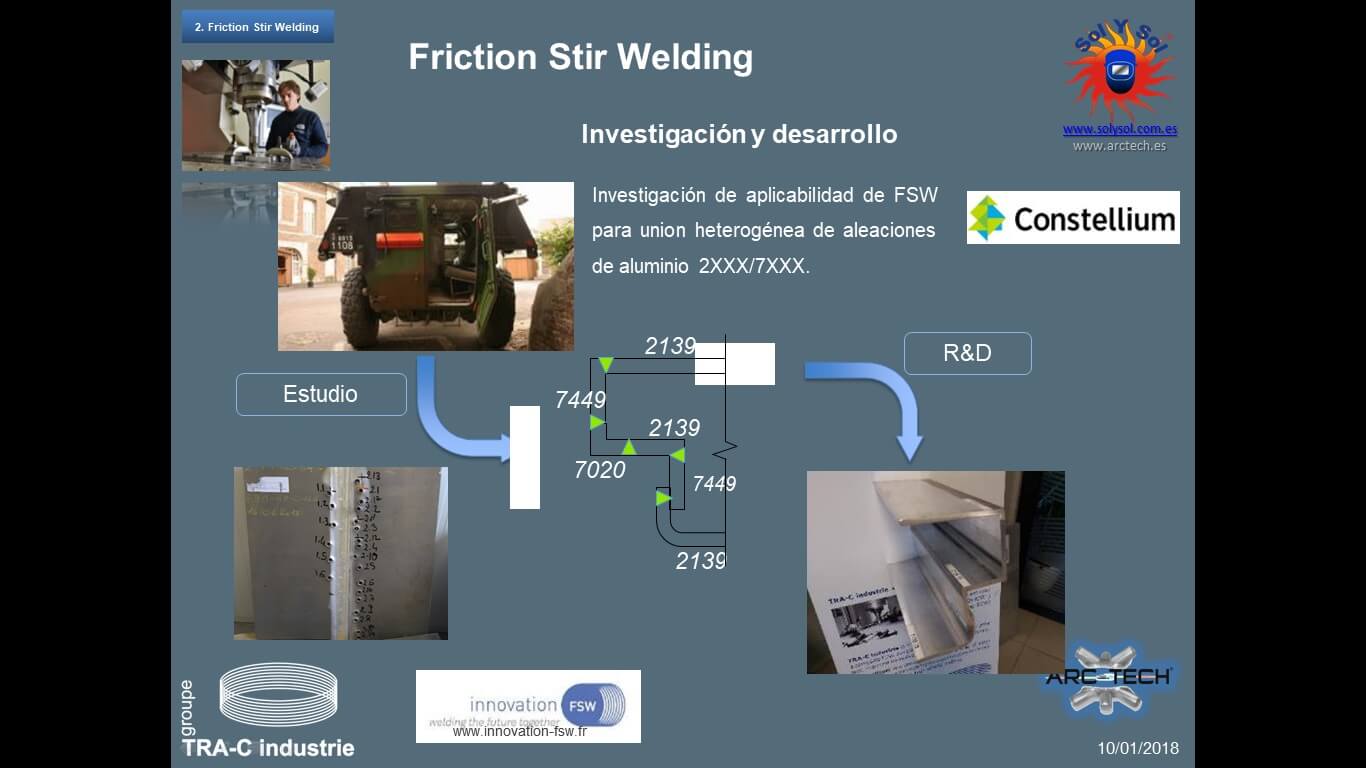

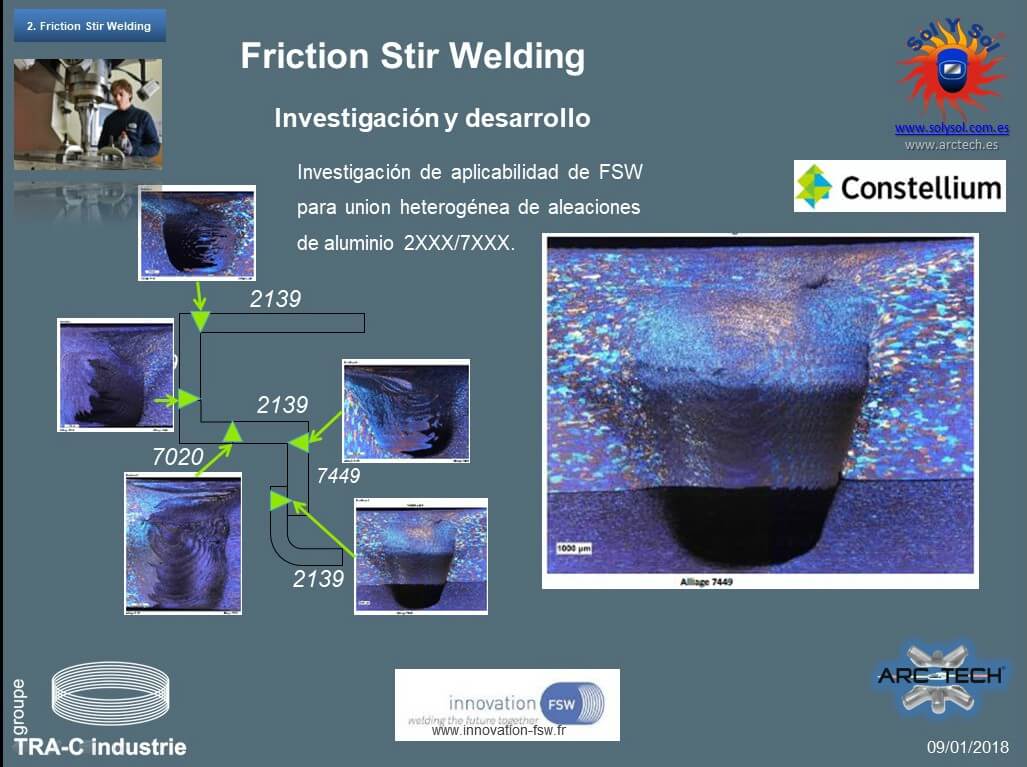

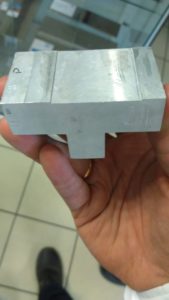

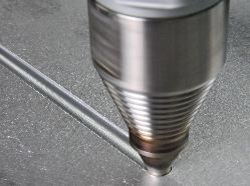

Example of dissimilar joint Al-7XXX/6XXX:

Example of dissimilar joint Al-7XXX/6XXX:

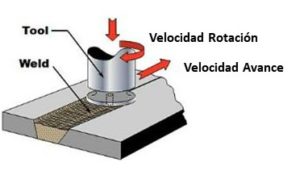

1. Knowledge and y experience with FSW from its inception at close collaboration with TWI

1. Knowledge and y experience with FSW from its inception at close collaboration with TWI

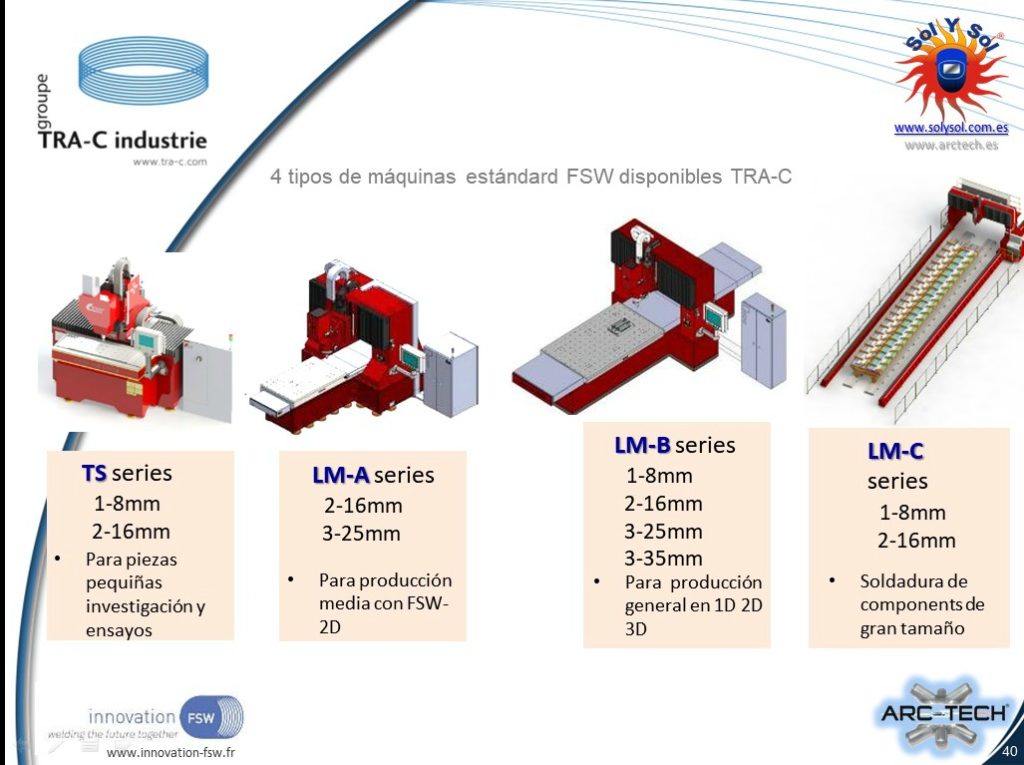

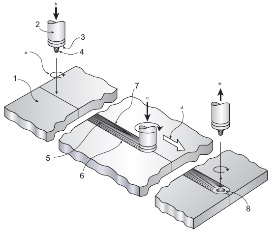

We have automatic installations for welding components of different dimensions and in variable production quantity depending on the need.

We have automatic installations for welding components of different dimensions and in variable production quantity depending on the need.